C.E.I.N.

Convergence Excellence Innovation Network

Engineering Services

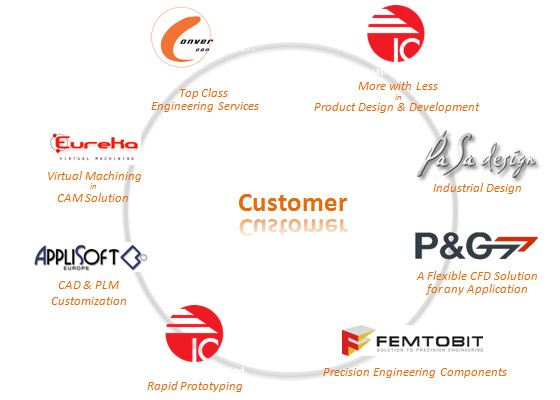

Customer Centric Network

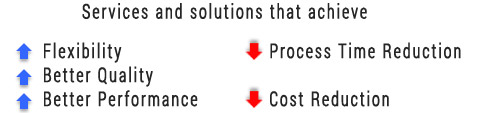

Speed & Flexibility

Innovation Code Ltd. (IC) is a Thai company providing Best in Class engineering services worldwide.

IC works in synergy with his Italian parent company Convergence Consulting s.r.l. based in Bologna.

Fields of Expertise

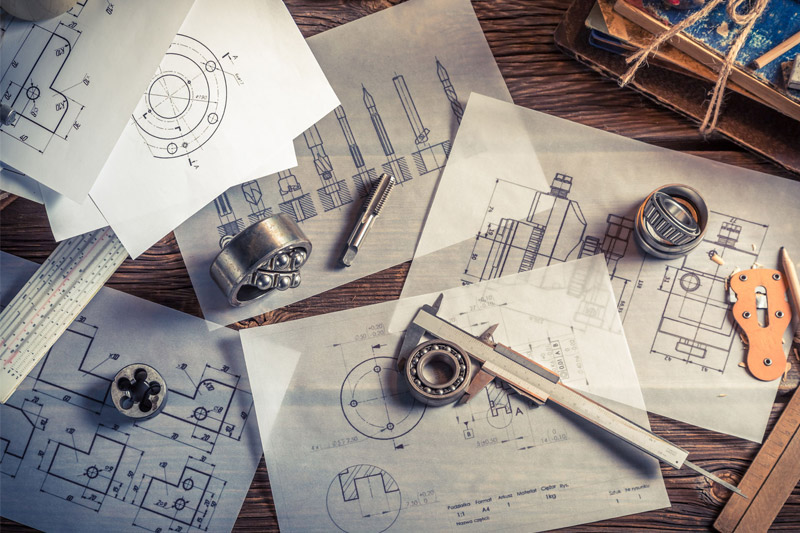

A worldwide network of high-skilled designer and engineering team, to fulfill our customers’ needs and accomplish any difficult product development tasks for our customers around the world.

read more

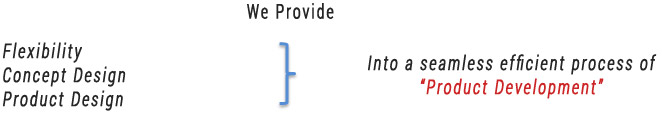

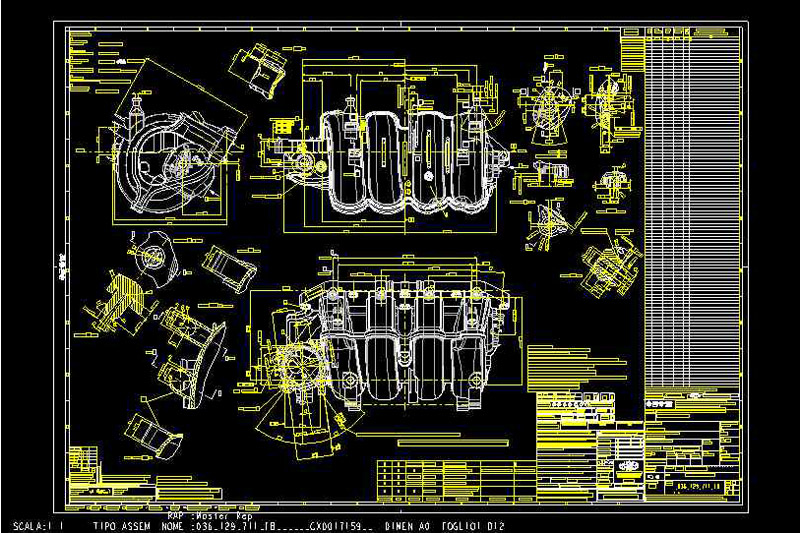

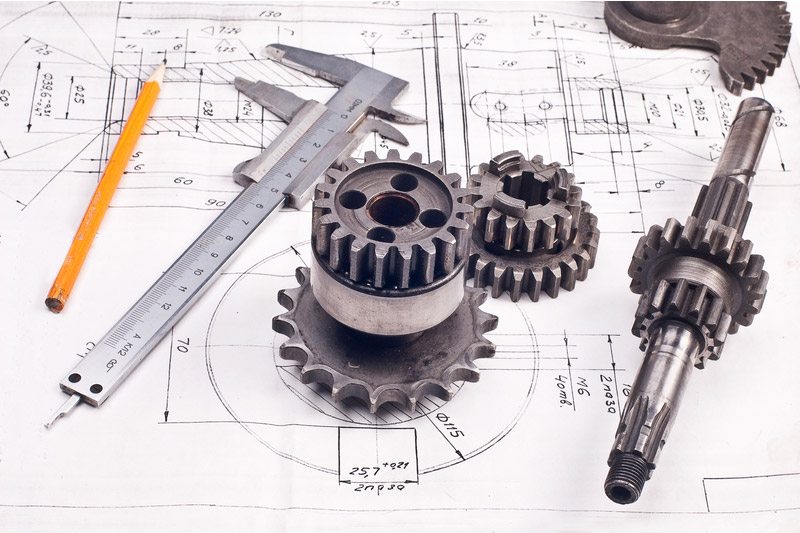

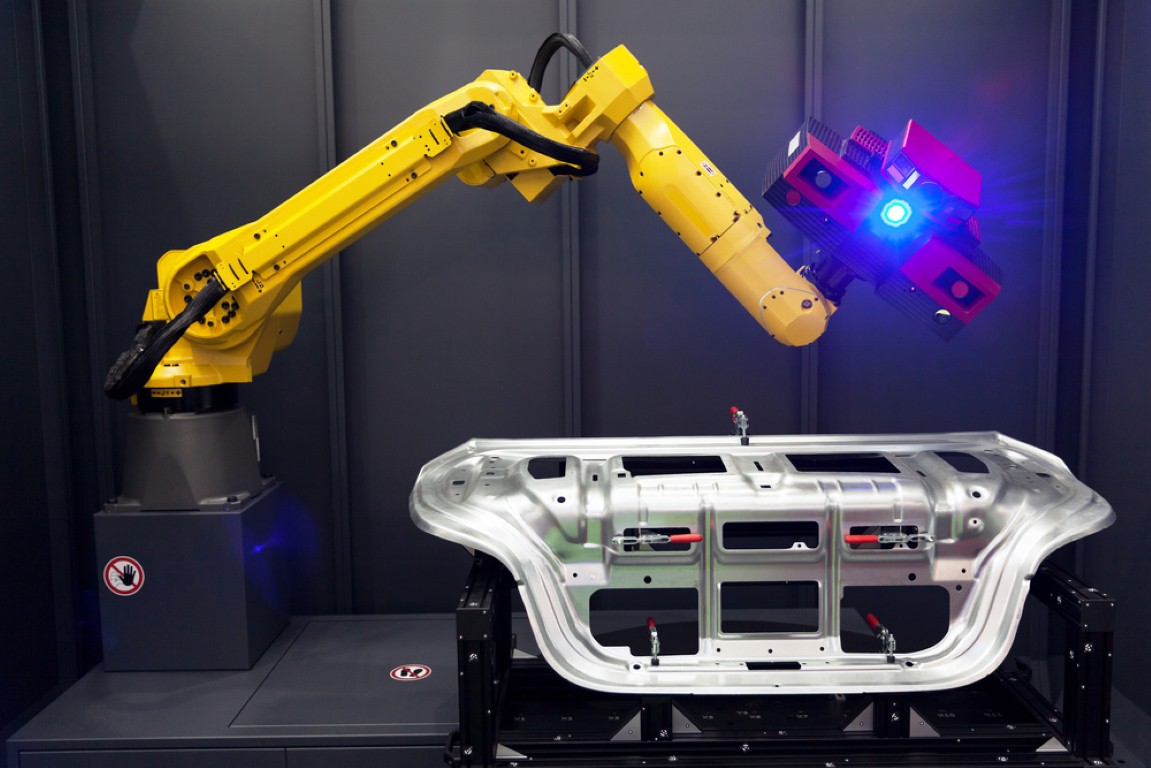

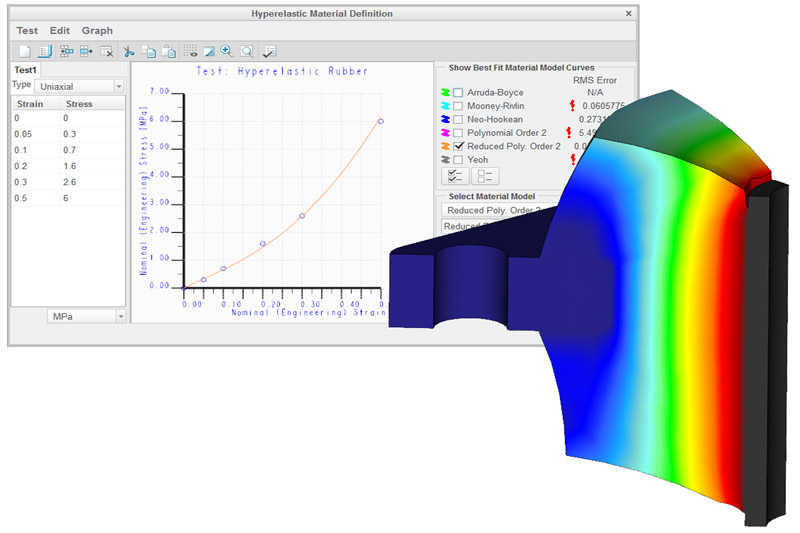

3D & 2D Design, 3D Animation, Engineering Expertise and Best-in-Class Manufacturing

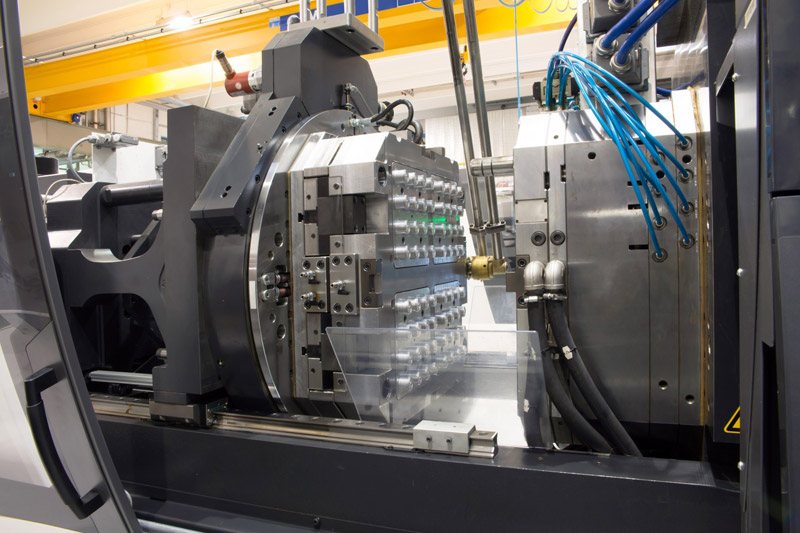

Precision Part & Assembly, Automation Machine, Injection Mold

& Injection Part, Stamping Die & Stamping Part

It’s more than 15 years that we help leader companies

Be an Innovation Booster for our Customer through Strong and Integrated Competence in Product Design & Development

Stay on the top of the technology curve to help our customer to reach their target of time-quality and cost in the process of new product development.

Design & co-design

Concept design

Innovation Code Ltd. No.9 G Tower Grand Rama 9, 31st Floor, Rama 9 Road, Huaykwang Sub-District, Huaykwang District, Bangkok 10310 THAILAND

Tel. : +662-239-1869

Fax. :